What is chemical recycling?

The chemical recycling of plastics can close the loop, even in the case of complex packaging.

The method transforms plastics into their basic chemical building blocks through a thermochemical process. These are reusable and are suitable for the renewed production of plastics.

Due to the further decomposition of the plastics, it is possible, among other things, to produce packaging that is 100 percent food safe. This also applies to mixed plastics and contaminated input materials.

The challenge? Chemical recycling leads to an increased energy requirement. We therefore always check which recycling is the more ecologically sensible method.

The solution: We collaborate with one of the most innovative chemical companies in the world to meet this challenge. In a unique project with a renowned brand manufacturer, we’ve demonstrated that we can close the loop.

Read more here

Close the loop with us

– together, united, and innovative

We want to create a real circular solution. We are not satisfied with inferior recycling or the incineration of plastic packaging.

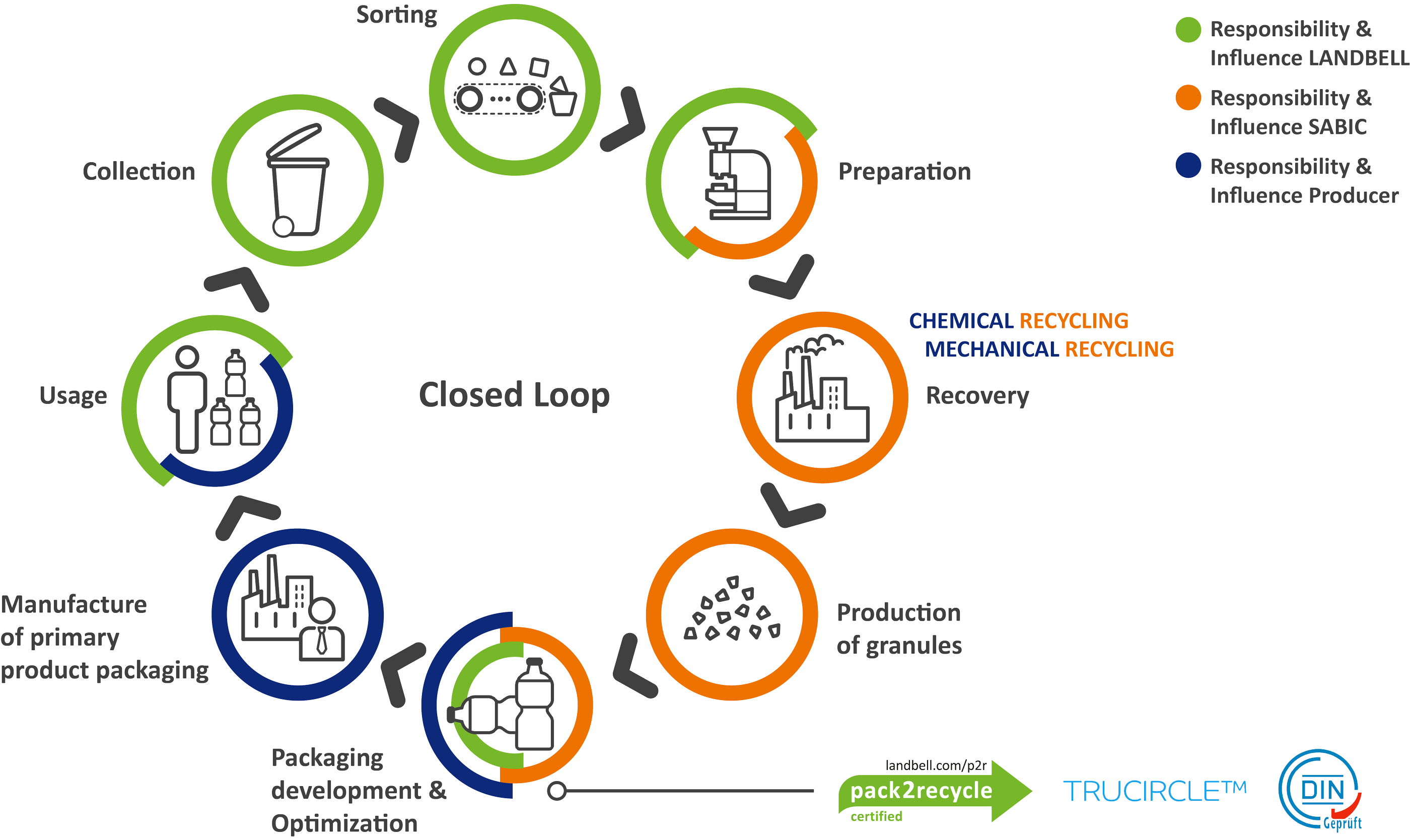

To achieve this, we have sought a partner who shares the same values. Together with SABIC, one of the world’s leading chemical companies, we are working to close the loop for hard-to-recycle plastic packaging. Here’s how:

Firstly, we identify which of the plastic packaging from the yellow bin/bag is suitable for the chemical recycling process. This only applies to plastic packaging that cannot be recycled in a high-quality or energy-efficient manner in mechanical recycling. We then prepare them for chemical processing.

Then SABIC takes over and splits the plastics provided into their basic chemical building blocks via a pyrolysis process. The chemical company then processes them and uses them to produce new plastics. These meet even the strictest quality requirements — such as hygiene standards for food packaging.

Important: we can only close the loop through working together with the manufacturers. They need to think sustainably and look for real circular solutions for their packaging and products.

Loop closed: 20 months of intensive cooperation pays off

In an innovative recycling project, Landbell, together with two companies, has succeeded in closing the loop for plastic food packaging.

At the end of 2020, Landbell partnered with SABIC, a leading chemical company, and Mars, a renowned manufacturer of confectionery, food stuffs and pet food.

The goal: To return plastic packaging – from the yellow bin/yellow bag –

to food packaging through chemical recycling. Otherwise, this packaging would only be converted to energy or inferiorly recycled in mechanical recycling. Due to this ground-breaking collaboration, the three companies were able to rise to the challenge of closing the loop.

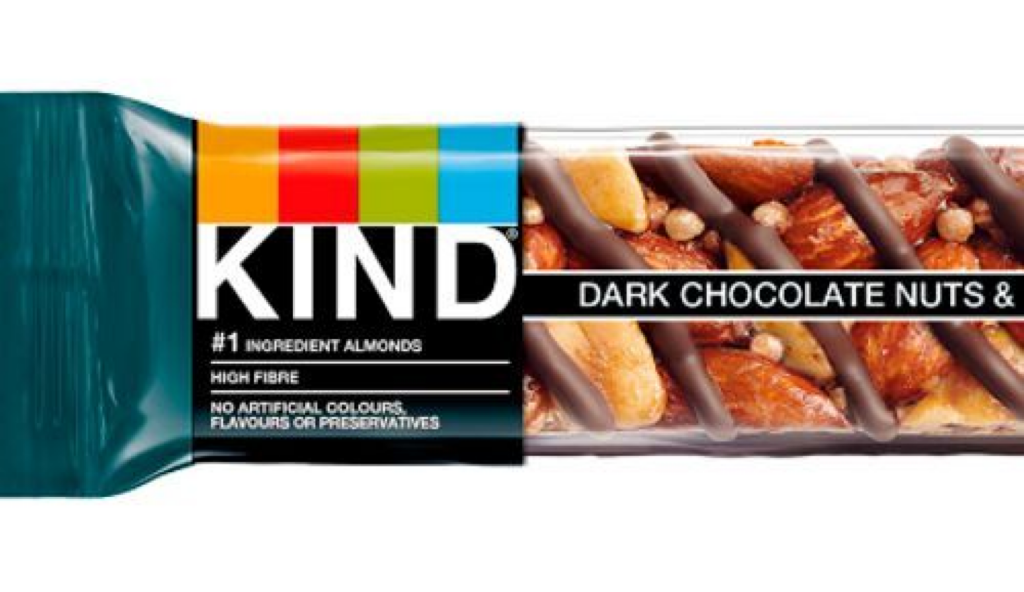

The result: After more than 20 months of intensive cooperation, Mars has been using recycled packaging material in its snack bar brand KIND® since October 2022. Landbell collected, sorted, and prepared this before SABIC processed it into certified polypropylene (PP).

The project demonstrates that we can close loops for complex plastic packaging ourselves. The requirement is that all parties contribute their expertise and stand up for the same goal.

Join us in closing the loop. Contact us at: closedloop@landbellgroup.com

Contact our experts now!

Landbell GmbH

Rheinstraße 4L

55116 Mainz

Germany

Phone: +49 (6131) 235652 – 0

Fax: +49 (6131) 235652 – 10

Email: info@landbell.de